Comprehending the Functionality of Membrane Layer Switches for Customer User Interface Instruments

The functionality of membrane switches over represents a significant innovation in interface layout, combining performance with visual adaptability. These switches run with a multi-layered framework that translates user interactions right into electrical signals, permitting both compact formats and durability versus ecological aspects. As sectors significantly focus on customer experience, recognizing the nuances of membrane layer switch innovation becomes crucial. What ramifications do these innovations hold for future applications, and how might they redefine user interactions throughout numerous tools?

What Are Membrane Buttons?

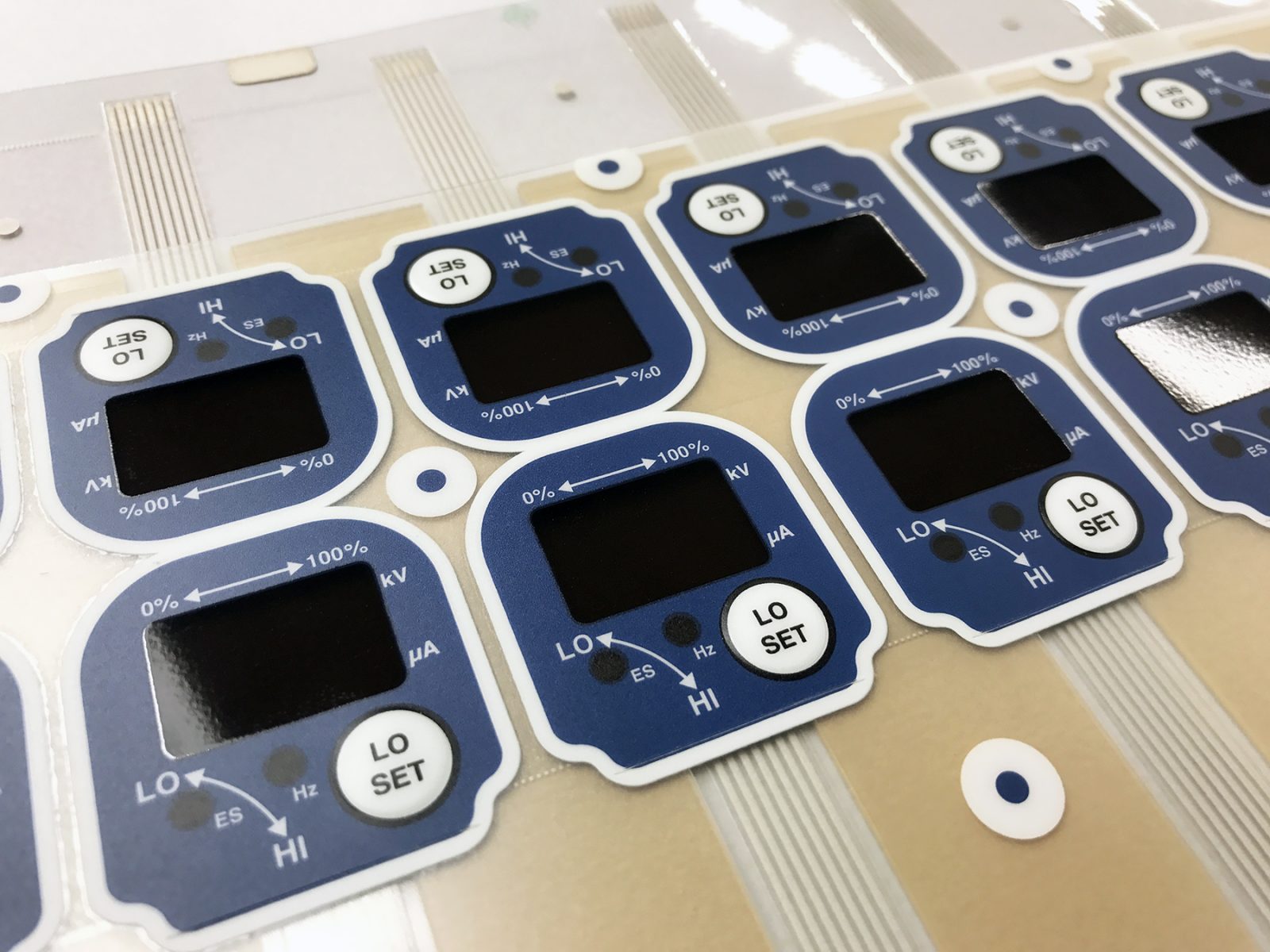

Membrane layer switches are cutting-edge interface devices that facilitate user communication with digital equipment. These functional parts are composed of multiple layers, consisting of a visuals overlay, spacer, and a published circuit layer. The design enables for a seamless integration into numerous digital tools, improving both the visual and practical facets of customer interfaces.

Membrane buttons are commonly used in a vast array of applications, from family appliances to industrial machinery and medical tools. Their building generally includes a slim account, making them an excellent selection for portable styles. The tactile comments given by these buttons can be engineered to meet certain individual choices, making sure effective interaction between the individual and the gadget.

Longevity is another considerable benefit of membrane layer switches, as they are resistant to dirt, wetness, and chemicals, which boosts their life expectancy sought after settings. Additionally, these buttons can be customized in terms of shape, size, and graphic design, permitting branding and user-specific features. Overall, membrane switches stand for a functional remedy for enhancing customer experience in electronic gadgets, combining functionality with aesthetic charm in a reliable manner.

How Membrane Switches Over Job

Operating on an uncomplicated concept, membrane layer switches make use of a layered construction to register individual input successfully. Each button consists of several layers, including a published circuit layer, a spacer layer, and a top graphic layer, which are created to interact effortlessly. When a customer presses the leading layer, it presses the spacer layer, bringing the conductive elements of the circuit layer into contact with each various other.

This call produces a shut circuit, indicating the tool to carry out a details function. The layout permits for different setups, including tactile feedback, which can boost the customer experience by supplying a physical sensation upon activation. The materials made use of in membrane layer buttons often include adaptable substratums, such as polyester or polycarbonate, which make sure longevity and durability against wear and tear.

Trick Advantages of Membrane Buttons

An additional significant benefit is their compactness. Membrane switches are slim and lightweight, which allows makers to conserve room in their tools without compromising capability. This function is especially valuable in applications where weight and quantity are critical factors to consider.

In addition, membrane layer switches are immune to dirt, moisture, and chemicals, enhancing their resilience. This resilience expands their life-span and lowers the need for frequent substitutes, causing cost savings with time.

Moreover, the responsive responses offered by membrane buttons can be optimized to boost customer communication. They can include features such as elevated switches or audible clicks, boosting usability and customer experience.

Applications Throughout Industries

Customer user interface tools making use of membrane layer switches are prevalent in a broad selection of industries, showcasing their flexibility and capability. Membrane Switch. In the medical field, membrane switches are integral to gadgets such as diagnostic devices and client monitoring systems, where their toughness and simplicity of cleansing are important for keeping health requirements. In a similar way, in the automotive market, these switches are utilized in control panel controls and infomercial systems, giving a smooth and modern-day interface for users.

Moreover, the consumer electronics market benefits from membrane switches in devices and portable devices, where portable design and straightforward user interfaces improve individual experience. Industrial applications likewise leverage membrane layer changes for control board in equipment and automation systems, emphasizing their toughness and resistance to rough environments.

In the aerospace and defense sectors, membrane buttons are utilized in cabin controls and equipment, where dependability and efficiency under extreme conditions are extremely redirected here important. Furthermore, the gaming sector progressively integrates membrane switches in controllers and gallery machines, adding to an appealing customer experience. Generally, the versatility of membrane switches allows their prevalent use across many markets, emphasizing their significance in contemporary interface layout.

Future Patterns in Membrane Switch Over Technology

Furthermore, making use of advanced materials, such as polycarbonate and polyester films, is anticipated to climb, providing enhanced longevity and resistance to environmental stressors. These materials contribute to the general long life of membrane layer buttons, making them suitable for harsher industrial applications.

Furthermore, the consolidation of clever modern technology, consisting of IoT connection, will certainly make it possible for membrane layer buttons to communicate with other devices and systems, assisting in an extra interactive customer experience. This fad straightens with the expanding need for clever tools throughout different markets, from health care to customer electronics.

Finally, personalization choices are expected to broaden, enabling producers to create bespoke services tailored to specific customer demands and choices. These advancements will position membrane layer buttons as necessary parts in the development of individual interface technology.

Conclusion

Finally, membrane layer changes represent a pivotal advancement in customer interface modern technology, using a trustworthy and flexible service for diverse digital applications. Their split building assists in More hints small layout, while attributes such as responsive comments enhance individual interaction. The durability versus environmental variables additionally solidifies their energy across several industries. As innovations in material scientific research and touch noticing modern technologies continue, the capability and applicability of membrane buttons are expected to increase, reinforcing their relevance in modern digital tools.